|

|||||||||||

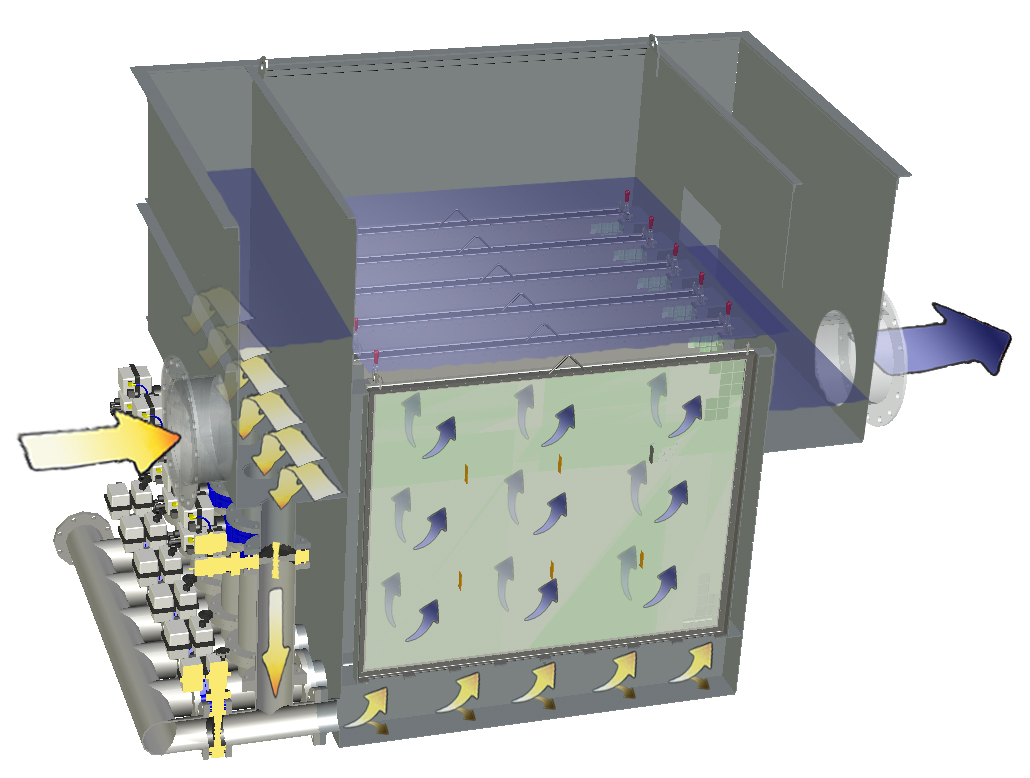

No Moving Parts - Simple OperationMFC Fixed Plate Cloth Media Filters are designed to provide tertiary wastewater treatment following municipal and industrial activated sludge, extended aeration, SBR and other advanced secondary treatment processes. The filter operates entirely by gravity, requiring only small head differential, making it ideally suited for municipal treatment facilities located in low lying areas or industrial facilities which cannot accomodate large piping or hydraulic changes.

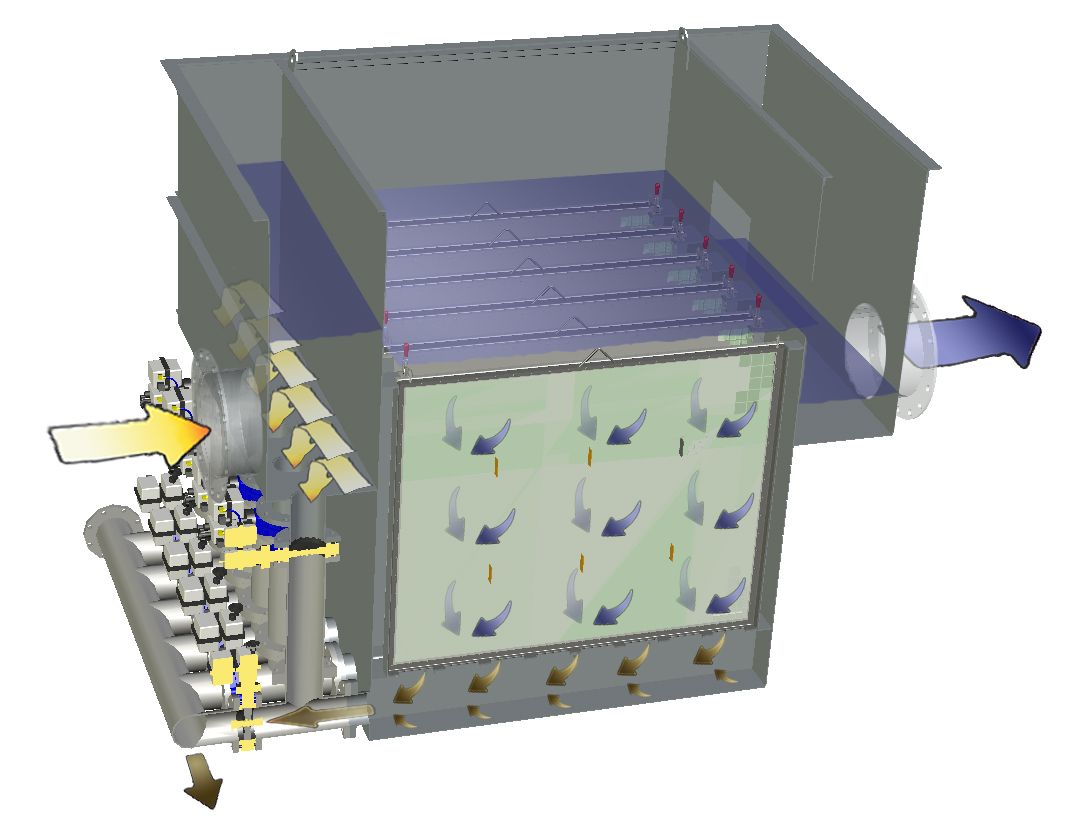

MFC cloth media filters feature a unique 'fixed' or static panel design, which limits mechanical wear and maintenance. Problematic backwash manifolds or spray bars and associated pumps are eliminated by using differential head generated by incoming flow to the other filter 'cells'. Each filter contains multiple filter segments, each of which is backwashed in sequence during the backwash stage, all while influent continues to enter the filter at all times.

Since filtration and backwash are produced by gravity, no pumps or vacuums, spray bars, or rotating elements are needed. This significantly reduces mechanical complexity and element wear, reducing installed cost and maintenance requirements.

VideosGeneral Filter Operation Air Scour Assisted Backwash |

|||||||||||

Reduced Redundancy & Maintenance |

|||||||||||

MFC's Fixed Plate Packaged cloth media filter systems utilize multiple isolated media panels within each tank to provide filtration & backwash of wastewater. This plurality of filter elements allows incoming water to continue to enter the filter system while individual filter elements are being backwashed or are removed from the system.

ALL internal components of MFC's cloth media elements are modularized and integral to the removable media element (and NOT attached to the tank). Therefore, ALL internal components for each element are removed from the tank while flow continues to the other online filter elements. This feature, in combination with an appropriate tank or basin design, allows elements to be removed, inspected and returned to service without decreasing system capacity or interrupting flow. ALL media within the system can be changed sequentially, while the remaining installed online elements treat the full design flow. MFC's Packaged cloth media filter systems come in a wide range of sizes to accomodate a variety of municipal, residential, & industrial applications with flow ranges from 10gpm up to 6.0MGD in a single filter. Elements range in size from 6sf of media per element up to 48sf of media per element, with systems available from 2x elements up to 8x elements in a single tank. Larger flows can be accomodated using multiple packaged filters in parallel or by using Modular Equipment for Concrete Basins |

All MFC equiptment is PROUDLY

|

||||||||||

Examples

|

|||||||||||

Downloads/Media: | Articles & Links: | ||||||||||

MFC BrochureDownload our latest brochure or contact MFC for product details & pricing. |

CA TITLE 22 REUSE:White Paper: CA tribal project uses fixed plate cloth media filters to achieve Title 22 Reuse.(Visit IWS Website) |

WATERWORLD MAGAZINE:Article: TX Reuse project features fixed plate tertiary cloth media filtration. |

NC AWWA-WEA:Paper: Tertiary Cloth Media Filtration Without Rotating Discs, Vacuum Pumps, or Spray Bars. |

TESTING UPDATE:Newsletter: Fixed Plate Cloth Media Filter Technology successfully tested at Madison, WI WWTP (MMSD) |

|||||||

MFC's Fixed Plate Cloth Media Filters & Weir Boxes - Proven Performance | |||||||||||

All information contained herein is property of Municipal Filtration Co., LLC (MFC). |

Navigation/Links: |

||||||||||